HIOKI RESISTANCE METER

Product may be available upon request. Please contact us on WhatsApp or email for more details

High-precision Portable Resistance Meter Measures from µ ohm to M ohm

Hioki DC resistance meters measure a broad range of resistance values at a high level of precision. The RM3548 is a high-precision, portable resistance meter capable of measuring resistance levels from microohms to megaohms, and is ideal for the testing and maintenance of large equipment, for example, measuring the winding and weld resistances in large motors and stators for hybrid and electric vehicles.

Key Features

0.02 % basic accuracy, 0.1 μohm max. Resolution, 1A max. Testing current

Measure from 0.0 μohm (testing current 1 A) to 3.5 Mohm

Easily record up to 1,000 data points in memory simply by applying the instrument’s probes

Smoothly capture temperature-rise test data using interval measurement

Portable design is ideal for maintenance and testing of large equipment

Portable resistance tester that’s ideal for low-resistance measurement and testing of large transformers and motors

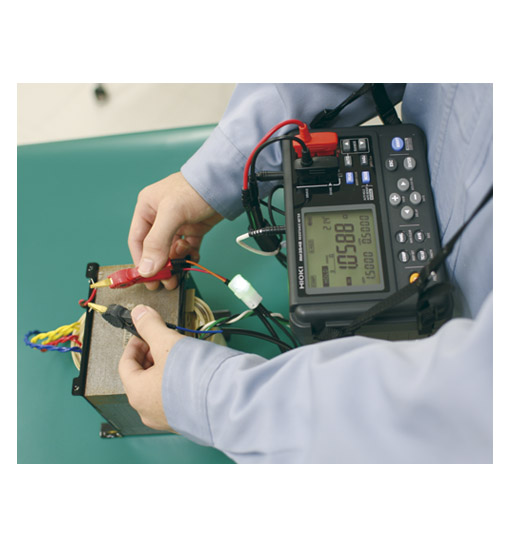

This resistance tester features a portable design that’s easy to use when performing maintenance work in the field. You can wear the instrument over your neck with the included strap, leaving both hands free to hold the clip-type leads while making measurements. The instrument can be powered by eight AA alkaline batteries for about 10 hours of measurement. (Operating time varies with measurement conditions.)

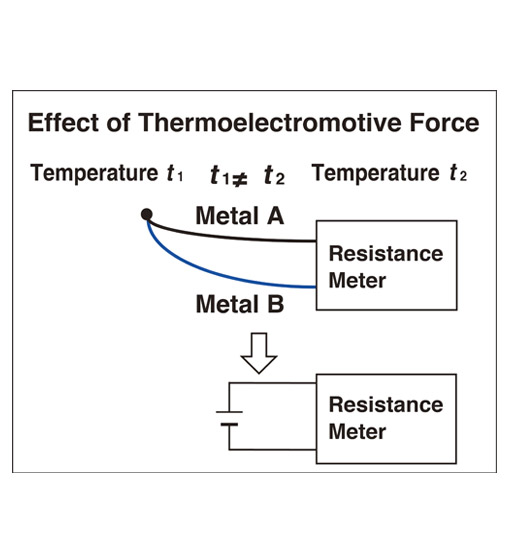

Reduce the effects of thermo electromotive force with the offset voltage correction

Thermo electromotive force refers to the potential difference that occurs at junctions between different metals (see figure). Specifically, the phenomenon occurs where measurement probes and measurement targets come into contact, and at connections between measuring instruments and measurement leads. The magnitude of this thermo electromotive force varies with the temperature of the measurement environment, increasing as the temperature difference grows. The RM3548 includes an offset voltage correction function that applies the measurement current in both the positive and negative directions and then uses the resulting detected voltages to eliminate the effects of thermo electromotive force.

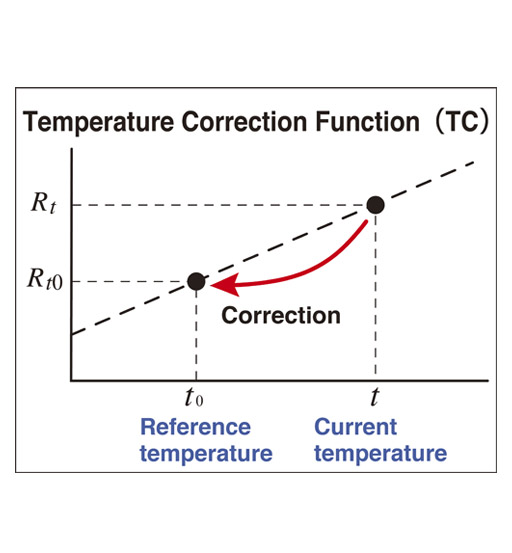

Correct resistance values, which vary with temperature, to a reference temperature with the temperature correction function

Temperature correction functions can convert readings to resistance values at a user-specified reference temperature and display the results, even for materials such as copper wire whose resistance varies with temperature. The RM3548’s temperature correction function converts the measured resistance value Rt at the current temperature t to the resistance value Rt0 at the reference temperature t0, as shown in the figure. The Temperature Sensor Z2002 (which comes with the RM3548) is used to perform temperature correction.

Product Video https://youtu.be/bIwSwWmTWkc